Textile digital printer F832

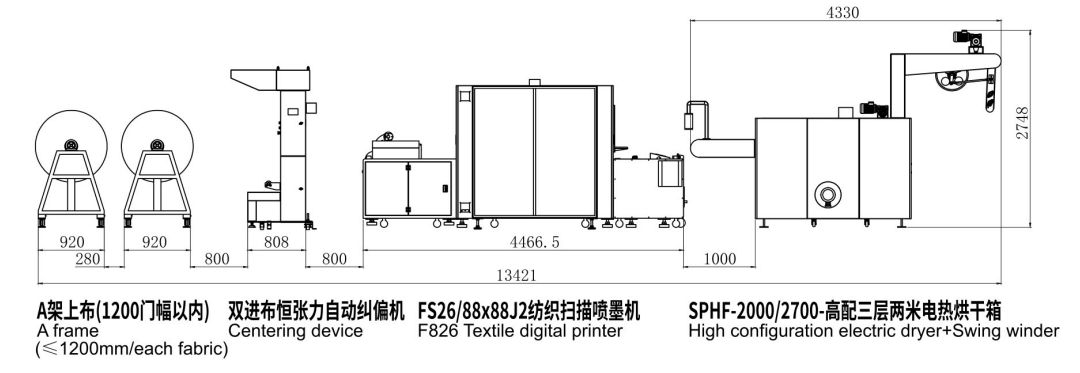

1.Structure & Stability: Robust steel beam structure and magnetic suspension motor enhance durability and precision, ideal for industrial use.

2.Versatile Print Heads: Offers a range of print head options, including Dimatix and Kyocera, supporting single and double color configurations for customization.

3.Ink Compatibility: Supports various inks, including high-energy disperse inks for direct fabric applications, allowing diverse printing techniques.

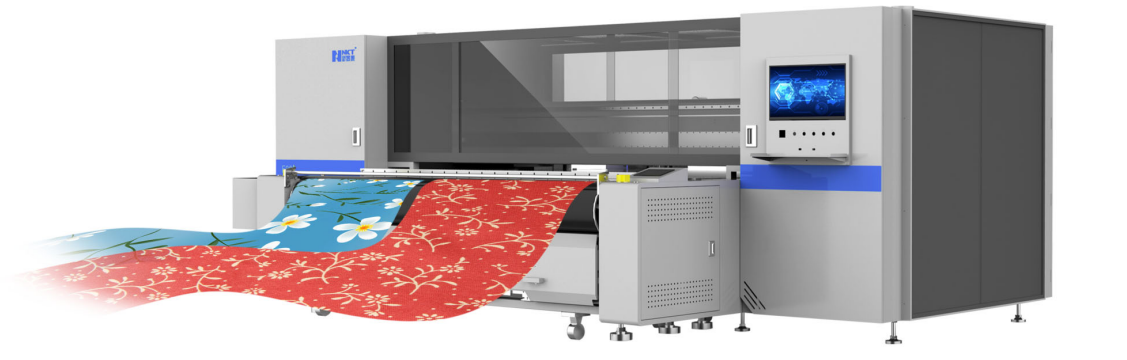

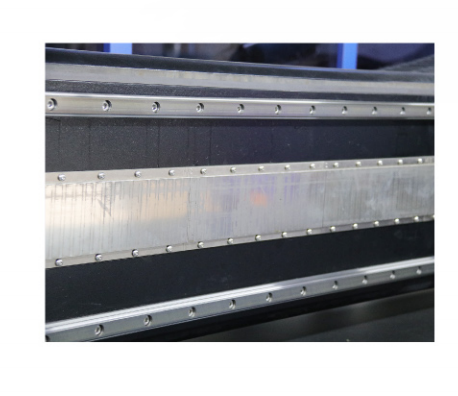

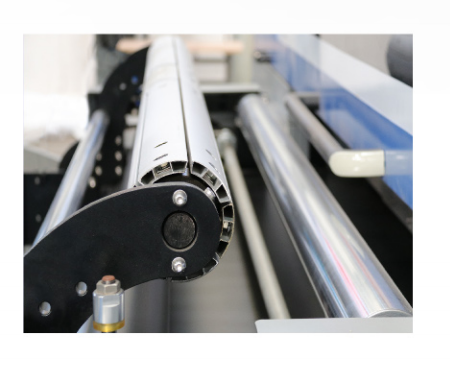

4.High-Speed Efficiency: Features a precision conveyor belt drive and advanced stretch and press unit for fast processing of various fabrics without quality loss.

5.Cleaning & Maintenance: Includes a double roller belt cleaning system and drying unit to ensure optimal performance and prevent contamination.

6.Impressive Output: Achieves speeds up to 1.2 meters per second with Kyocera print head, capable of 10,000 meters daily for scaling operations.

7.Flexible Winding Options: Accommodates jumbo and small rolls with single or double station winding, enhancing operational flexibility.

8.Market Versatility: Capable of printing on paper and direct fabrics, reducing investment risks and addressing diverse printing needs effectively.

|

Main Technical Parameter |

|||

|

Max Printing Width |

3200mm or customized |

||

|

Number of Color Bars |

6 Color/8 Color/10 Color |

||

|

Quantity of Print Heads |

Kyocera single color head:64 pcs Kyocera dual color head:32 pcs |

||

|

Printing Speed(According to different design and fabric) |

2 PASS |

(Single door width)1300㎡/h |

(Double door width)1200㎡/h |

|

3 PASS |

(Single door width)900㎡/h |

(Double door width)860㎡/h |

|

|

Ink Color |

C、M、Y、K、BL、OR、GR、MB、R |

||

|

|

Windows 10,64 bit,CPU:intel Core 11700 processor,HDD:1T,2GB graphics,RAM:32GB |

||

|

RIP Software |

Neo Stampa |

||

|

|

Moveable press unit, Conveyor cleaning/Drying unit,Print head protection unit,Linear motor scanning system,Print head cleaning system |

||

|

|

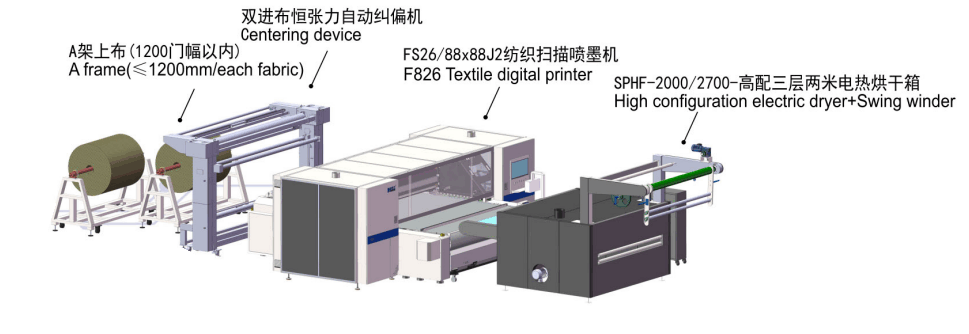

Dryer(Electric/Steam),Auto constant tension unit,Unwinder(A frame),Winder(swing type) |

||

|

Working Conditions |

Power:380V±10%,Air Pressure>0.5MPa,Temperature:20-30℃,Humidity:50-70% |

||

|

Installed Power |

56KW(Digtal Printer 28KW+Dryer 28KW) |

||

|

Overall Dimension(LxWxH) |

6235x4480x2100mm |

||

|

Weight |

6000KG |

||

|

Production Kyocera head |

||||

|

Model |

Pass |

Printing Production(㎡/h) Single width Double Width |

||

|

F818 |

64 heads Kyocera EX600 |

1 |

2400 |

2200 |

|

2 |

1300 |

1200 |

||

|

3 |

900 |

860 |

||

|

32 heads Kyocera KJ4B-0300 |

2 |

1300 |

1200 |

|

|

3 |

900 |

860 |

||