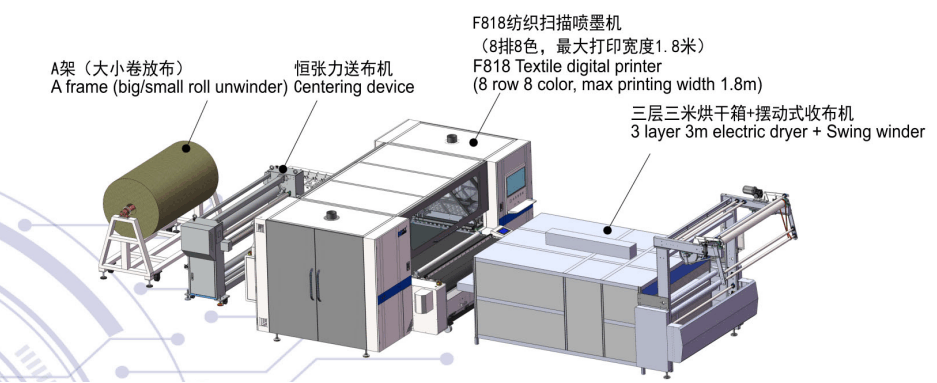

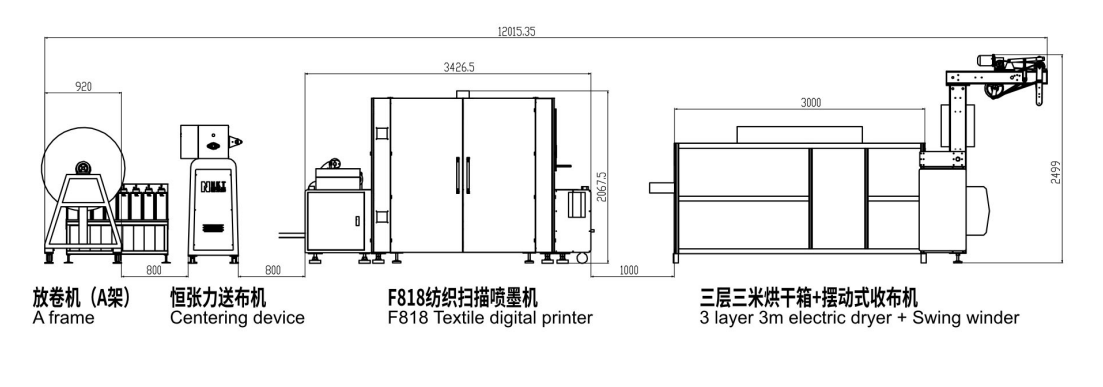

Textile digital printer F818

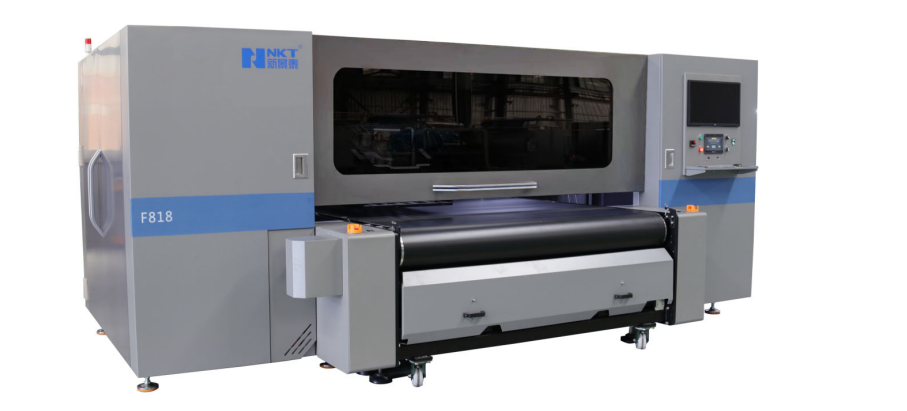

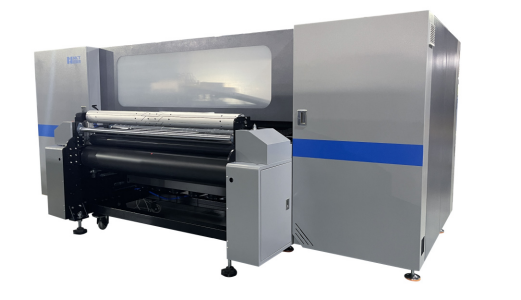

1.The steel beam structure, magnetic suspension motor, and double linear guide rail ensure high precision and minimize issues.

2.Choose from various print heads, including Dimatix and Kyocera, available in single or double color configurations.

3.Compatible with disperse, reactive, and pigment inks, including high-energy disperse inks for direct fabric printing.

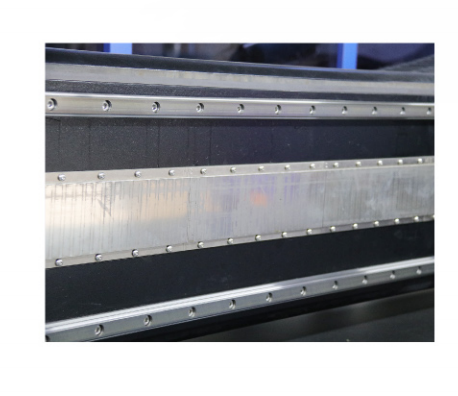

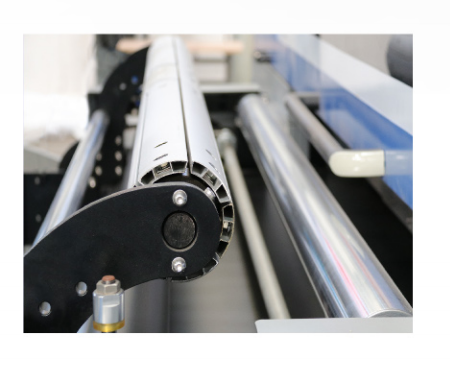

4.Features a high-precision conveyor belt drive system and a mature stretch and press unit, suitable for various fabrics at high speeds.

5.Equipped with a double roller belt cleaning system and drying unit for diverse fabric production.

6.Offers multiple unwinding and winding options for both jumbo and small rolls, with single or double station winding.

7.Compatible with both paper and direct fabric printing, allowing for market adaptability and reduced investment risk.

|

Main Technical Parameter |

||

|

Max Printing Width |

1800mm or customized |

|

|

Number of Color Bars |

6 Color/8 Color/10 Color |

|

|

Quantity of Print Heads |

Kyocera single color head:64 pcs Kyocera dual color head:32 pcs |

|

|

Printing Speed(According to different design and fabric) |

2 PASS |

800㎡/h |

|

3 PASS |

600㎡/h |

|

|

Ink Color |

C、M、Y、K、BL、OR、GR、MB、R |

|

|

|

Windows 10,64 bit,CPU:intel Core 11700 processor,HDD:1T,2GB graphics,RAM:32GB |

|

|

RIP Software |

Neo Stampa |

|

|

|

Moveable press unit, Conveyor cleaning/Drying unit,Print head protection unit,Linear motor scanning system,Print head cleaning system |

|

|

|

Dryer(Electric/Steam),Auto constant tension unit,Unwinder(A frame),Winder(swing type) |

|

|

Working Conditions |

Power:380V±10%,Air Pressure>0.5MPa,Temperature:20-30℃,Humidity:50-70% |

|

|

Installed Power |

52KW(Digtal Printer 24KW+Dryer 28KW) |

|

|

Overall Dimension(LxWxH) |

4800x3430x2070mm |

|

|

Weight |

5300KG |

|

|

Production Kyocera head |

|||

|

Model |

Pass |

Printing Production(㎡/h) |

|

|

F818 |

64 heads Kyocera EX600 |

1 |

1440 |

|

2 |

800 |

||

|

3 |

600 |

||

|

32 heads Kyocera KJ4B-0300 |

2 |

800 |

|

|

3 |

600 |

||