New King Time Digital Textile Printer, the best choice for high cost performance

The land of southern Guangdong comes early in spring, and the red cotton flowers bloom in the spring. Strict prevention and control measures, without fear of the Covid-19. At present, Covid-19 situation has entered a critical period. In response to the call of the government, New King Time has done a good job in Covid-19 prevention and control, and under the deployment of scientific Covid-19 prevention, it has taken multiple measures at the same time, and its employees have returned to work one after another to resume normal production in 2020!

Wear masks, temperature measurement pass, prepare hand gel, disposable gloves and other protective articles, staff work in shifts, keep a safe distance, do not gather, use video conference. On the basis of ensuring the quality, we should speed up the work scientifically to improve the construction efficiency, and try our best to catch up with the pending delivery date. Under reasonable arrangement, the production order will soon return to normal. During the Spring Festival, a large number of orders for textile digital printers have been completed and delivered successively, which have been installed and used successfully in the customer's factories. We should pay attention to Covid-19 prevention, resumption of work, scientific organization and arrangement of production, careful debugging, guarantee both quality and quantity to deliver the machines.

NKT textile digital printer has a wide range of product lines, including single pass paper print and direct fabric print models, high-speed digital printer and roll to roll paper printer. At the same time, we can choose Kyocera single or dual color print head, Dimatix print head and Epson S3200 industrial print head, all of which have mature

The newly designed KINGJET F series 4 row high-speed digital textile printer with Kyocera dual color head is equipped with 4 rows of 16 Kyocera dual color heads, 8-color solution, and 2 pass printing speed up to 400m²/ h. To achieve both color and speed, for large output, low investment threshold customers, high cost performance, low initial investment, in line with the current market environment. At the same time, KINGJET F series can also choose 4 rows of 32 Kyocera single color heads, 8-color solution, 1 pass printing speed up to 950m²/ h. It can achieve high precision and large output at the same time, and is also one of the mainstream configurations selected by current capacity upgrading customers. Both of above two types of print head can work with reactive, acid and disperse.

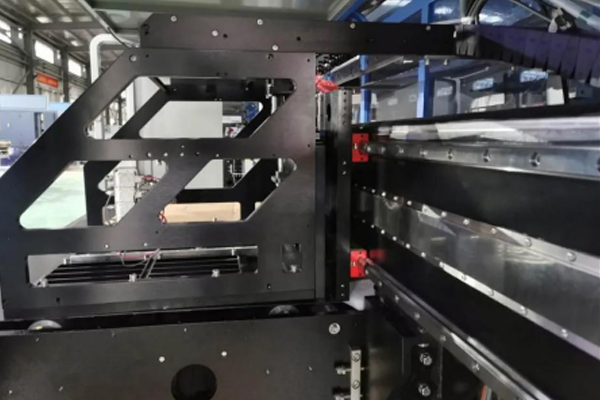

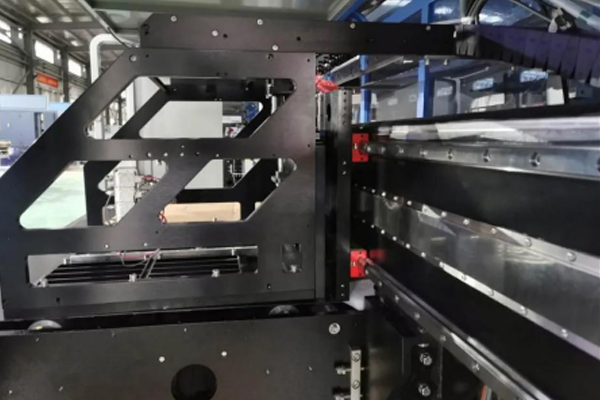

Kingjet F series machine has a stable and reliable structure to further optimize the heavy-duty industrial grade frame. The precise transmission system and conveying system, printing hardware and software have been upgraded after years of iterative improvement, and the printing accuracy, speed and stability of the equipment have reached the international advanced level. A variety of winder and unwinder unit are available. Professional design fashion appearance, compact structure. The F series model was launched in December 2019, which is very popular with customers at home and abroad. Customers place orders one after another and some machines are delivered in time before the spring festival, which solves the urgent need of customers' production and is used stably in customers' factories.

Direct selling and agency are carried out simultaneously as NKT sales strategy. New King Time has established sales and service centers in Shaoxing and Shengze. The main foreign service office are located in India, Pakistan, Vietnam and Bangladesh. Provide customers with one-year warranty for the whole machine and print head, and local service office support 24-hour response service.

Entering the 27th year, NKT always insists on the concept “pursue the top quality, provide the best service, and keep advance!”, insisting on continuous product improvement and new product research and development, providing the market with products in line with the world's advanced technology, and making our efforts for the development of textile digital printer!

Wear masks, temperature measurement pass, prepare hand gel, disposable gloves and other protective articles, staff work in shifts, keep a safe distance, do not gather, use video conference. On the basis of ensuring the quality, we should speed up the work scientifically to improve the construction efficiency, and try our best to catch up with the pending delivery date. Under reasonable arrangement, the production order will soon return to normal. During the Spring Festival, a large number of orders for textile digital printers have been completed and delivered successively, which have been installed and used successfully in the customer's factories. We should pay attention to Covid-19 prevention, resumption of work, scientific organization and arrangement of production, careful debugging, guarantee both quality and quantity to deliver the machines.

NKT textile digital printer has a wide range of product lines, including single pass paper print and direct fabric print models, high-speed digital printer and roll to roll paper printer. At the same time, we can choose Kyocera single or dual color print head, Dimatix print head and Epson S3200 industrial print head, all of which have mature

The newly designed KINGJET F series 4 row high-speed digital textile printer with Kyocera dual color head is equipped with 4 rows of 16 Kyocera dual color heads, 8-color solution, and 2 pass printing speed up to 400m²/ h. To achieve both color and speed, for large output, low investment threshold customers, high cost performance, low initial investment, in line with the current market environment. At the same time, KINGJET F series can also choose 4 rows of 32 Kyocera single color heads, 8-color solution, 1 pass printing speed up to 950m²/ h. It can achieve high precision and large output at the same time, and is also one of the mainstream configurations selected by current capacity upgrading customers. Both of above two types of print head can work with reactive, acid and disperse.

Kingjet F series machine has a stable and reliable structure to further optimize the heavy-duty industrial grade frame. The precise transmission system and conveying system, printing hardware and software have been upgraded after years of iterative improvement, and the printing accuracy, speed and stability of the equipment have reached the international advanced level. A variety of winder and unwinder unit are available. Professional design fashion appearance, compact structure. The F series model was launched in December 2019, which is very popular with customers at home and abroad. Customers place orders one after another and some machines are delivered in time before the spring festival, which solves the urgent need of customers' production and is used stably in customers' factories.

Direct selling and agency are carried out simultaneously as NKT sales strategy. New King Time has established sales and service centers in Shaoxing and Shengze. The main foreign service office are located in India, Pakistan, Vietnam and Bangladesh. Provide customers with one-year warranty for the whole machine and print head, and local service office support 24-hour response service.

Entering the 27th year, NKT always insists on the concept “pursue the top quality, provide the best service, and keep advance!”, insisting on continuous product improvement and new product research and development, providing the market with products in line with the world's advanced technology, and making our efforts for the development of textile digital printer!