AN AUSPICIOUS START OF NKT

The first quarter of 2022 is over, how is NKT?

After Spring Festival, we are back to work!

NKT EXPORT TEAM

INSTALLATION

After returning to work, the workshop became busy immediately.

Installation, acceptance, shipment...We just hope we can deliver the machines and parts to customers as soon as possible.

Machines in our workshop

Rustic tile equipments, digital inkjet printers, more and more machines are finished by our workers.

LOAD THE CONTAINERS

In the first quarter, we shipped a large number of machines to Pakistan, Vietnam, Bangladesh, India, Saudi Arabia and other countries.

When our machines arrive to the destination port, our agents or customers will unload the containers safely.

AFTER-SALES SERVICE

Our after-sales service elites clear up their mood in a short time, then go to the production line to assist customers in installation and commissioning so that the line can put into production on time.

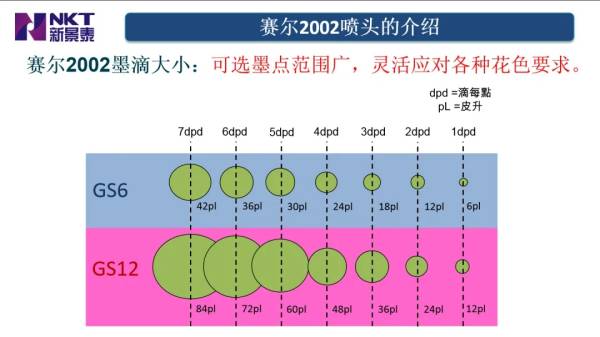

XAAR 2002 INTRODUCTION

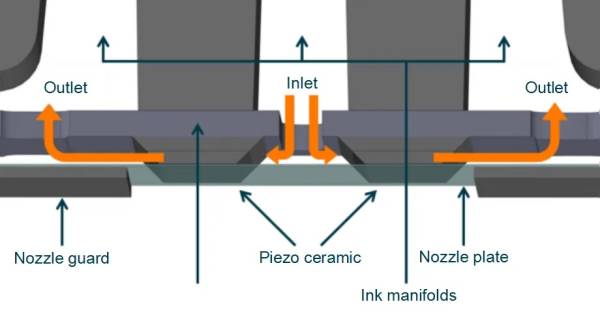

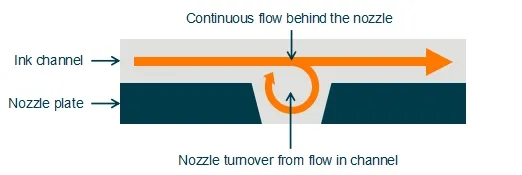

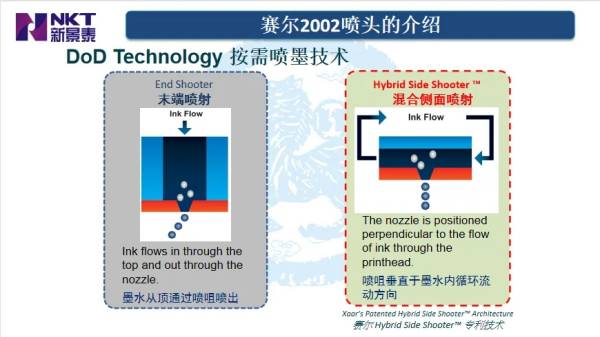

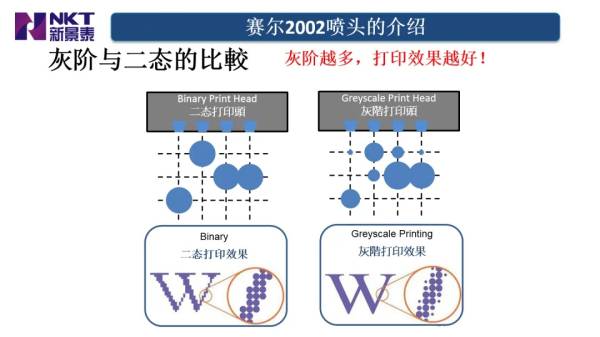

XAAR 2002 Printhead

Six characteristics of XAAR 2002

-

High flow rate: 100 ml/min to 150 ml/min directly behind the nozzle;

-

Constantly moving: Prevents sedimentation;

-

Self cleaning: Debris and air bubbles carried away;

-

Self priming: Channels actively refilled rather that capillary flow alone

-

Reduced latency: Longer uncapped time from continuous nozzle turnover

- Constant temperature: Stable jetting conditions at the nozzle.

We have regular meeting with XXAR UK headquarters .As a result, we have made great progress from the improvement of the core technology of the printheads, the upgrading of software, and the process of the whole machine manufacturing technology.

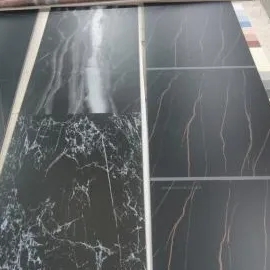

PRODUCT

Five years of hard work, and the advanced stability of the machine, make NEW KING TIME have more than 100 customers which use 2 series printhead. Not only China's major production areas, but Southeast Asia, Middle East, Africa, South America and other production areas have our loyal customers. In the past five years, there was no serious complaints, and the repeat purchase rate reached 70%. In recent years, it has also continuously attracted the attention and choice of domestic head enterprises and professional OEMs that have strict requirements for output and quality.

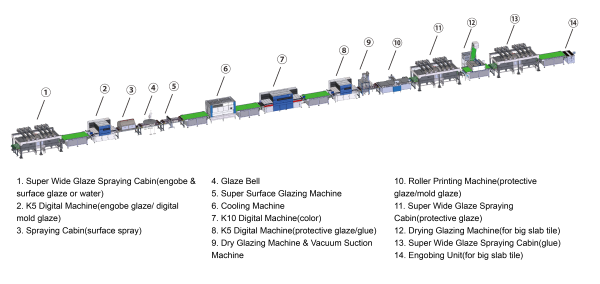

GLAZE LINE EQUIPMENT

High Pressure Airless Machine

Feature:

1.High pressure,maximun up to 20KG/cm².

2.Touch screen control.

3.Constant working pressure.

Glaze Bell

Feature:

1. For the application of a uniform film of thick or viscous glaze on the tiles surface.

2. Feeding group with max level indicator with glaze flow.

3.Adjusting valve with pole.

Super Surface Glazing Machine

Feature:

-

Achieve even coating film and fine and fine adjustment of thickness thanks to the high precision coating head.

-

Opening system,easy to clean thoroughly.

-

It allows the application of glaze with wide range of viscosity, average dispersion.

Super Wide Glaze Spraying Cabin

Feature:

-

Can install with single/double row spray gun,situable for large capacity.

-

Touch screen+PLC intelligent control,more concise.

-

Glaze quantity trimming design,more convenient for operators.

-

Compatible with 65°/95°/110° spray nozzle.

-

Work with high pressure airless machine, automatically tracking for pressure stabilization.

Fast Cooling Machine

Feature:

-

Two powerful compressors can be combined in one group.

-

Fitted with double filter modules, reduce the dust,ease the cleaning and changing of cartridge.

-

With automatic temperature adjusting system for variable temperature setting requirments.

- Mounted with touch screen control panel for setting and displaying the actual temperature at each relevant location conveniently.

Drying Machine

Feature:

1.Equipped with intelligent temperature control system.

2.With powerful infrared lamps,the heat transmission is fast and efficient.

3.Equipped with convection blowers to reduce the pollution.

4.Can be incorporated into the glazing line industry 4.0 management platform.

Website: https://www.nktmachinery.com/

Youtube:https://www.youtube.com/channel/UCmOei0XkVitlq1Zq2sgIBLw

WhatsApp/Wechat: 0086 13702348776